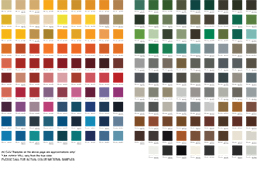

Frame Colors

Click Here for RAL standard Color chart

All Color Samples on the above page are approximations only! Your monitor WILL vary from the true color.

PLEASE CALL FOR ACTUAL COLOR MATERIAL SAMPLES.

Powder Coating with TruZinc Rich Primer and TGIC Polyester

Powder Coating with TruZinc Rich Primer and TGIC Polyester

Shot blasted steel

Factory applied TruZinc rich finish primer (6000 hr. salt spray tested)

TGIC Polyester “Super-Durable” top coat (1000 hr. salt spray resistant)

(5-6 mil min. thickness on exterior)

Hot-Dip Galvanizing

Cleaned steel

Factory applied hot dipped zinc galvanizing

Optional TGIC polyester powder coat may be applied to galvanizing

Anti-Graffiti Clear Coat

Helps prevent vandals from defacing property with graffiti clear coat

Avoid the graffiti damage eyesore and costly graffiti removal

.

.

.

.

Blast Only

Blast only for the “rust look”.

Shade shelter architecture for the recreational and park industry requires excellent durability, environmental protection, corrosion resistance and other quality factors. And certainly these gazebo colors need an attractive appearance. Powder coating is a great greener alternative than other surface finishes with a variety of frame colors and pergola colors to choose from. Additionally powder coating provides enhanced durability for all outdoor architectural applications.

Classic Recreation offers offers standard and optional powder coating and hot dip galvanizing for the best gazebo colors and finishes. Many frame colors are available as displayed in the above RAL color chart. These finish products have extremely long-lasting life cycles, excellent edge coverage, provide superior mar resistance, and contain no VOCs. Additional benefits include leed credits, application efficiency of 95% or higher, and very competitive applied cost.

We also offer TruZinc Rich Finish Primer to protect the steel ferrous substrate. This primer uses two protection mechanisms. First, the primer acts as a barrier to water and electrolytes increasing the electrical resistance of the corrosion cell. Second, the primer provides zinc which acts as a sacrificial anode. This TruZinc Primers is the benchmark for corrosion resistance in the industry.